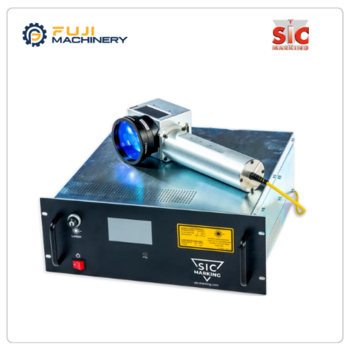

I104 HD LASER MARKING HEAD

5 (1 đánh giá)

Fiber laser is the latest ultra-efficient, enduring and easy to implement marking technology. To meet ISO quality requirements, product traceability is essential. This is why laser marking is used by manufacturers to automate traceability operations and thus guarantee 100% control of their process.

Thanks to its superior power, our integrated laser i103 HD marks with contrast on all types of materials (steel, aluminum, stainless steel, titanium, plastics ...). Logo

SIC Marking Group offers competitive products that strictly meet our customer's marking needs and have a fast ROI. Our laser experts and our technical teams are available to perform your marking tests in real situations on your parts and recommend the most appropriate parameters to your specifications.

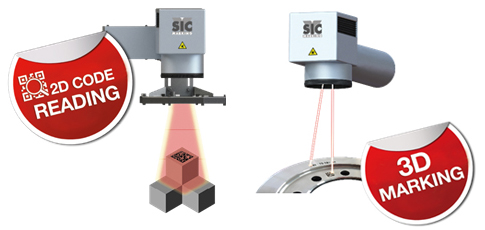

Various options such as 3D marking or integrated vision system can be added at any time if our customers wish so.

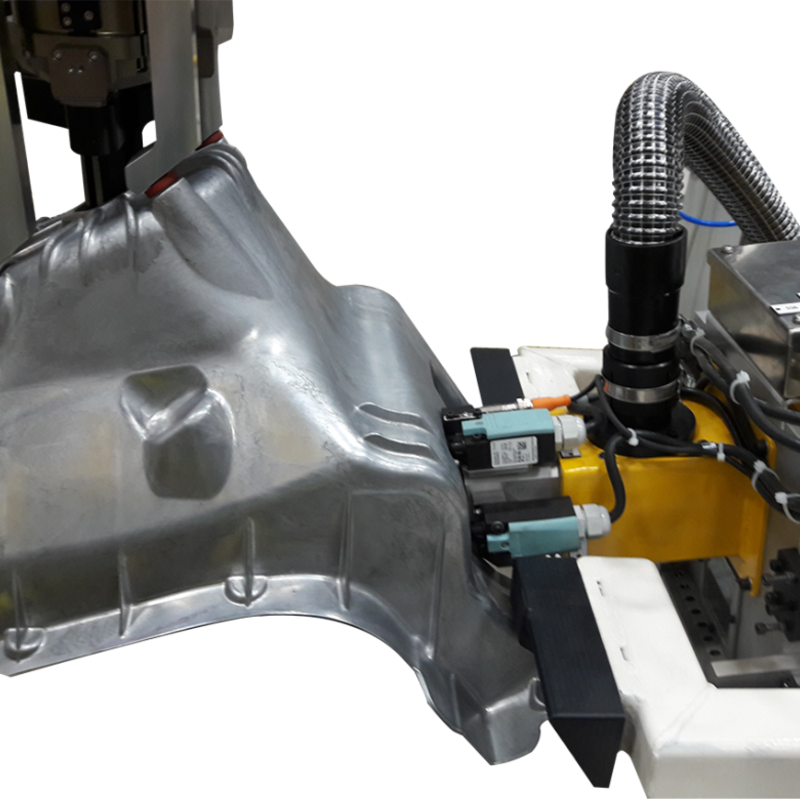

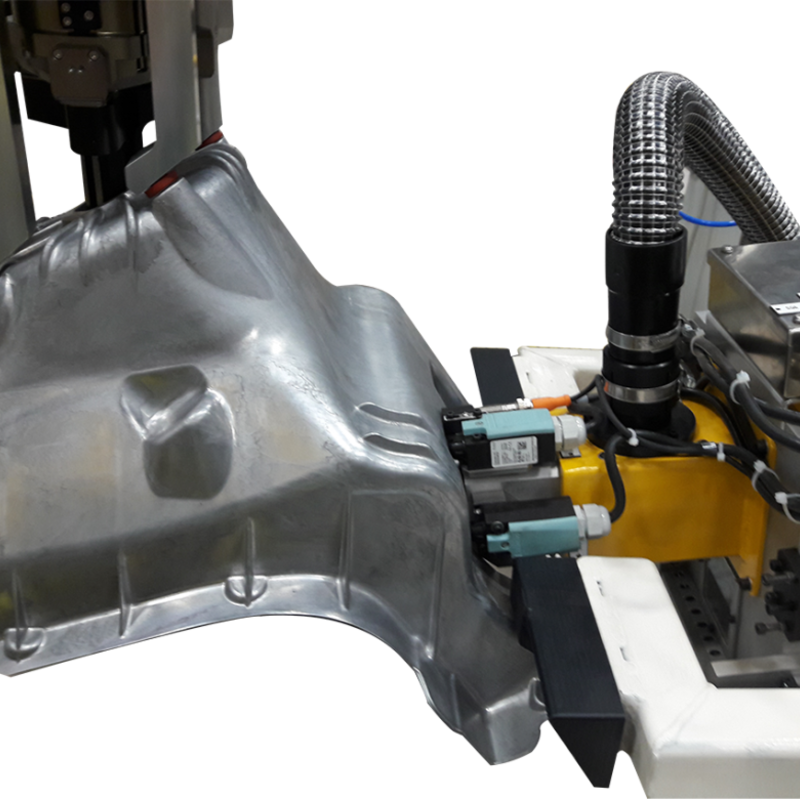

HIGH QUALITY MARKING

Strong contrast on aluminum and plastic parts.

.png)

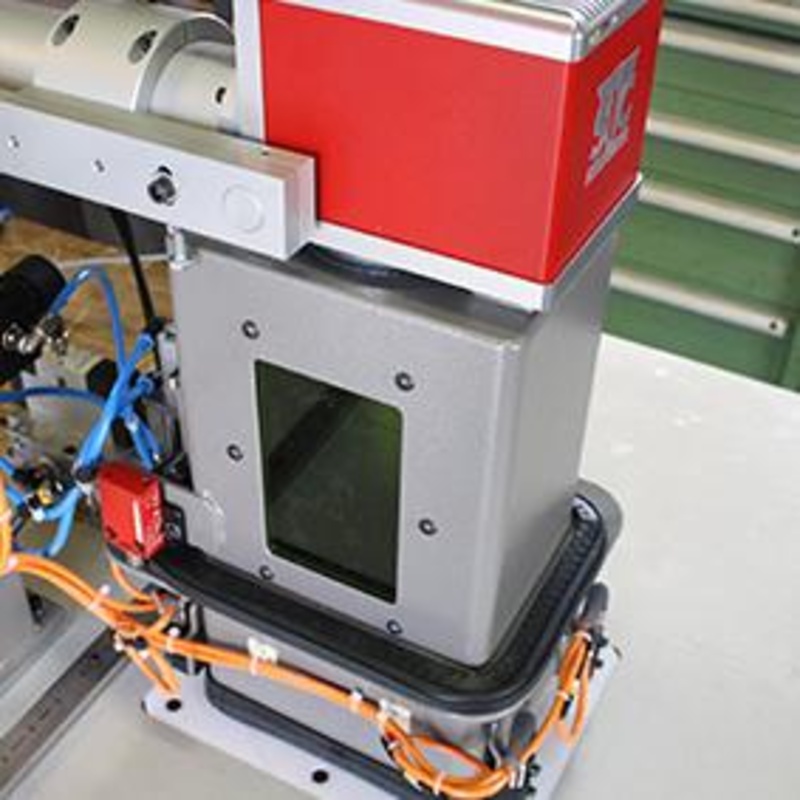

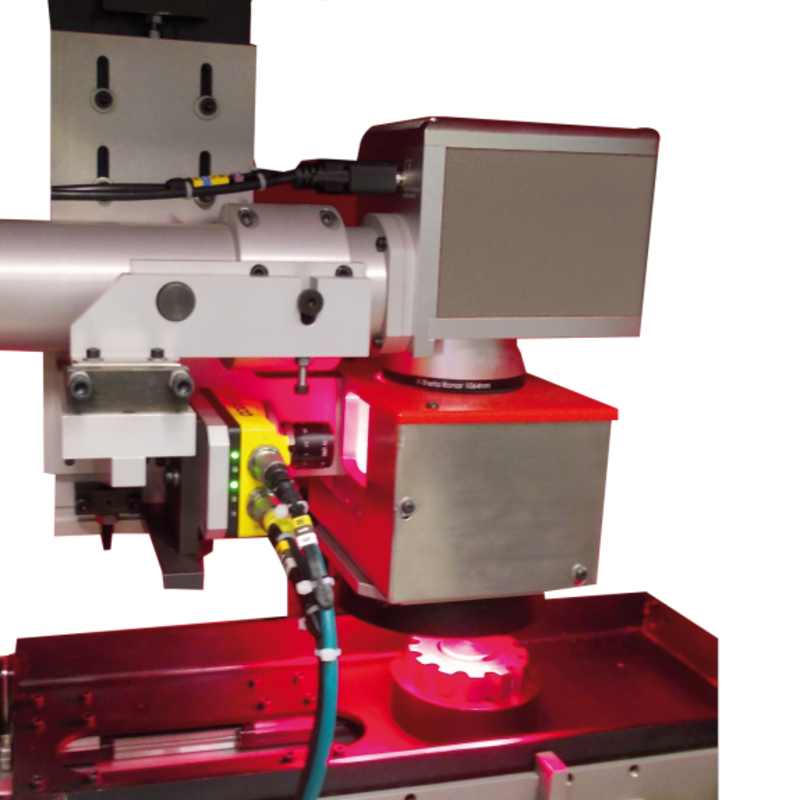

VERSATILITY

Adjustable pulse duration: marking on all types of materials.

.jpg)

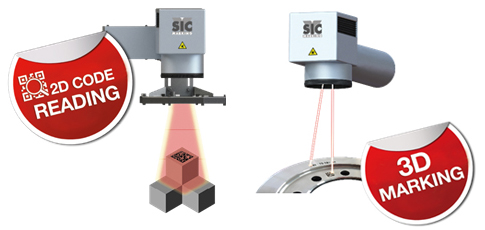

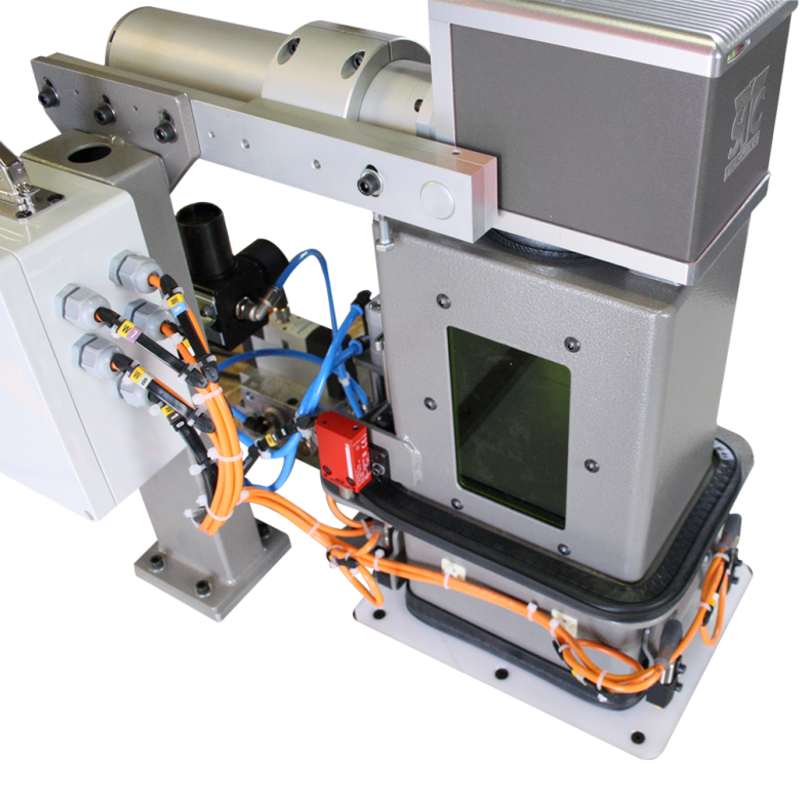

EASE OF INTEGRATION

Reduced size and weight of the laser marking head.

.jpg)

MECHANIC FEATURES

- Marking Window: 60 x 60 mm / 100 x 100 mm / 170 x 170 mm / 220 x 220mm / 300 x 300mm (contact us)

- Focal Distance: please download the i103 HD product sheet

- Weight of Controller: 19 kg

- Weight of Marking Head: 5 kg

- Security: Class 4 (EN60825-1 standard)

- Control: Standalone Mode (without PC)

ELECTRONIC FEATURES

The i104 HD fiber laser marking solution has been designed to operate with our Fiber Unit controller.

- Source: Pulsed Ytterbium Fiber Laser

- Operation Mode: Pulsed (10 à 1000 kHz)

- Pulse duration: 2 ns to 200 ns

- Wavelength: 1064 nm

- Optical Fiber Length: 3 m

- Average Power: 20W

- Peak Power: 7 kw

- Positioning/Focus: Built-In Laser Pointer

- Cooling: Air-Cooled Only

STEERING SOFTWARE

i104 HD laser marking equipment operates on standalone mode, connected to the production PLC. The creation and modification of files can be done any PC with a Windows OS using the SIC Laser Advanced software. A full range of customizable parameters are available which allow the user to optimize cycle time and improve contrast and colors by changing the speed, frequency, and power settings.

COMMUNICATIONS

- RS 232 / Ethernet interfaces

- Profibus, Profinet, Ethernet/IP (optional cards)

- I / O for cycle management

- Test COM software

OPTIONS

- 3D MARKING FUNCTION: AUTOMATIC ADJUSTMENT OF THE MARKING AREA

- INTEGRATED VISION FUNCTION

- COMMUNICATION CARDS

- AUTOMATIC Z AXIS 50-250MM STROKE

- FUME EXTRACTOR

Various options such as 3D marking or integrated vision system can be added at any time if our customers wish so.

HIGH QUALITY MARKING

Strong contrast on aluminum and plastic parts.

.png)

VERSATILITY

Adjustable pulse duration: marking on all types of materials.

.jpg)

EASE OF INTEGRATION

Reduced size and weight of the laser marking head.

.jpg)

AAdmin

Welcome, honored guests. Please leave a comment, we will respond soon