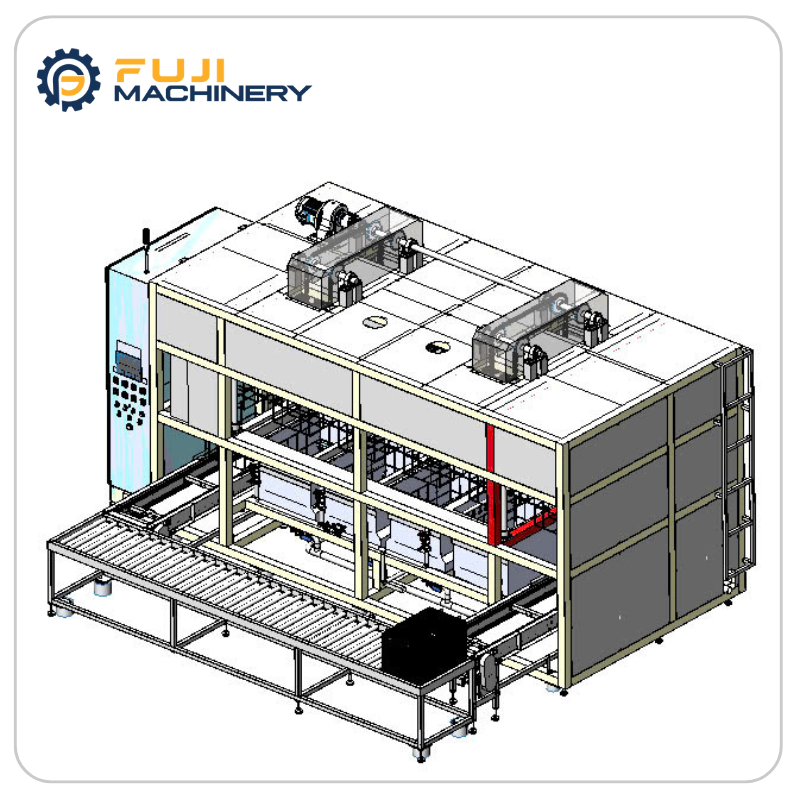

Ultrasonic Cleaner

5 (1 đánh giá)

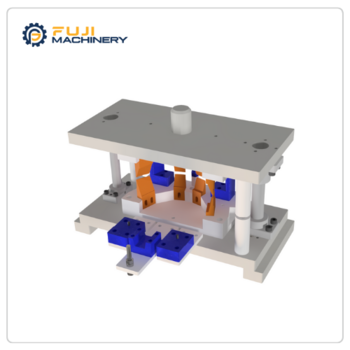

The FUJI Ultrasonic Cleaning Machine uses high-frequency ultrasonic wave technology to thoroughly remove oil, dirt, and contaminants — even in narrow gaps and small components. The system features an automatic 4-stage process: ultrasonic cleaning, hot water rinsing, and drying, which enhances cleaning efficiency, reduces labor and maintenance costs, and protects product quality.

It is ideal for industries such as machinery, electronics, automotive, medical devices, jewelry, and watches.

The FUJI Ultrasonic Cleaning Machine is an advanced device designed to clean parts, components, and industrial equipment quickly, evenly, and efficiently. It applies high-frequency ultrasonic technology combined with an automatic control system, providing an optimal cleaning solution for manufacturers in industries such as machinery, electronics, medical, automotive, jewelry, watches, and many others.

KEY FEATURES

- High-frequency ultrasonic technology: Ultrasonic waves generate microscopic bubbles in the cleaning solution, effectively removing oil, dirt, and contaminants even narrow gaps and small grooves.

- Intelligent temperature control system: Equipped with an HMI screen and temperature controller, allowing precise adjustment of cleaning temperature and duration to suit different product types.

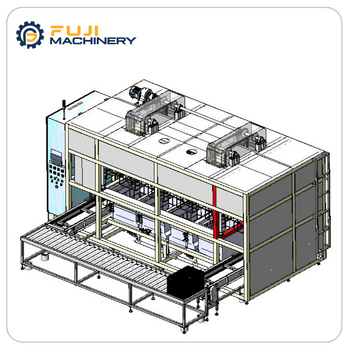

- Safe & Stable Control System: All control components are housed in a separate electrical cabinet, ensuring stable operation and minimizing risks.

- SUS 304 Stainless Steel Conveyor: Corrosion-resistant and highly durable, it offers excellent load capacity, reduces vibration and noise, and enhances operational stability and precision.

- Powerful Lifting Mechanism: The aluminum frame structure can support loads up to 500 kg, ensuring safe and flexible product handling.

- 4-Stage Automatic Cleaning Process: Ultrasonic cleaning (Stage 1) – Ultrasonic cleaning (Stage 2) – Hot water rinsing – High-pressure air drying.

Automatic Diagnostic & Error Alert System: Monitors and alerts for any operational issues, enhancing reliability and safety.

Operation Monitoring & Data Storage: Tracks cleaning cycles, temperature, time, and other parameters to support analysis and maintenance.

Eco-friendly Design: Minimizes the use of chemicals and water, meeting green standards and protecting the environment.

MAIN FUNCTIONS

- Deep and thorough cleaning: Effectively removes oil, grease, dirt, and contaminants product surfaces.

- Ensures complete cleanliness: Dual ultrasonic cleaning stages combined with hot water rinsing and high-pressure air drying.

- Saves time and increases productivity: The automated process reduces manual cleaning, improving production efficiency.

WIDE APPLICATIONS

- Precision machining & metal processing (CNC, turning, milling, grinding, laser cutting)

- Electronic component manufacturing, PCB, IC, and sensors

- Automotive, motorcycle, and engine parts industries

- Medical equipment & laboratory instruments

- Aerospace & defense industries

- Jewelry, watches, and high-end products

BENEFITS OF USING FUJI ULTRASONIC CLEANER

- Superior cleaning performance: Achieves 95–98% deep cleanliness, even for small parts and narrow gaps.

- Cost efficiency: Reduces labor, chemical, and maintenance costs.

- Safe & eco-friendly: Automatic cleaning process with environmentally friendly solutions minimizes operator risk.

- Extends product lifespan: Protects components damage and maintains consistent product quality.

The FUJI Ultrasonic Cleaner is the optimal solution for manufacturing enterprises that require precise component cleaning, enhanced productivity, and reduced operational costs.

Contact FUJI Machinery today for a free consultation and a detailed quotation tailored to your production needs.

FUJI Machinery Co., Ltd.

Address: Thach Khoi Industrial Cluster 1, Thach Khoi Ward, Hai Phong City, Vietnam

Phone: (+84) 220 628 4666 | (+84) 964 658 958

Email: info@fujimachinery.com.vn

Website: https://fujimachinery.com.vn/

AAdmin

Welcome, honored guests. Please leave a comment, we will respond soon