Small vibration fatigue testing machine Syclus

5 (1 đánh giá)

Therefore, Acroedge has released a device that can perform repeated fatigue testing.

Demonstration Video

What is Syclus?

Syclus is a small vibration fatigue tester developed for use on a wide range of materials such as textiles, films, rubber, etc. It is intended to evaluate the life span of a product and observe the changes that the material undergoes, and by measuring multiple samples it is possible to obtain information on the consistency of quality and the location of defects.

Measurement image

Over time, the material weakens and changes its strain response (different materials have different stress responses) until the material fails.

Sample test example

Rubber fatigue test sample data: Rubber Sample No. 1

▪ Operating mode: constant strain ▪ Oscillation cycle: amplitude + -0.4 mm, 10 Hz ▪ Test duration: 42 hours

The delay in displacement versus stress cycle (red curve) seen in this graph is characteristic of viscoelastic materials.

Comparing the results after one hour (1) and 24 hours (2), a decrease in the maximum and minimum load can be seen.

Looking at the test time dependence of the load-displacement curve obtained as in graphs 1 and 2, the material was subjected to constant strain mode.

You can see that the load required to vibrate is reduced.

Rubber fatigue test sample data: Rubber Sample No. 2

By continuously monitoring the load (red curve), any sudden changes in the sample condition can be detected without being overlooked.

If a sudden increase in force is detected due to material breakage, the three cycles immediately prior to that are saved. (The force value threshold that is considered a sudden increase in force must be set by the user in advance.) In the above experiment, it can be seen that the force measurement value becomes zero when the rubber breaks. The data up to this zero is considered to be the data at the time of breakage and is saved. In the first few hours, the weakening of the rubber due to repeated loading can be seen.

To obtain accurate results, it is necessary to set conditions according to the properties of the material sample. The response of tension and contraction force to temperature changes differs depending on the material.

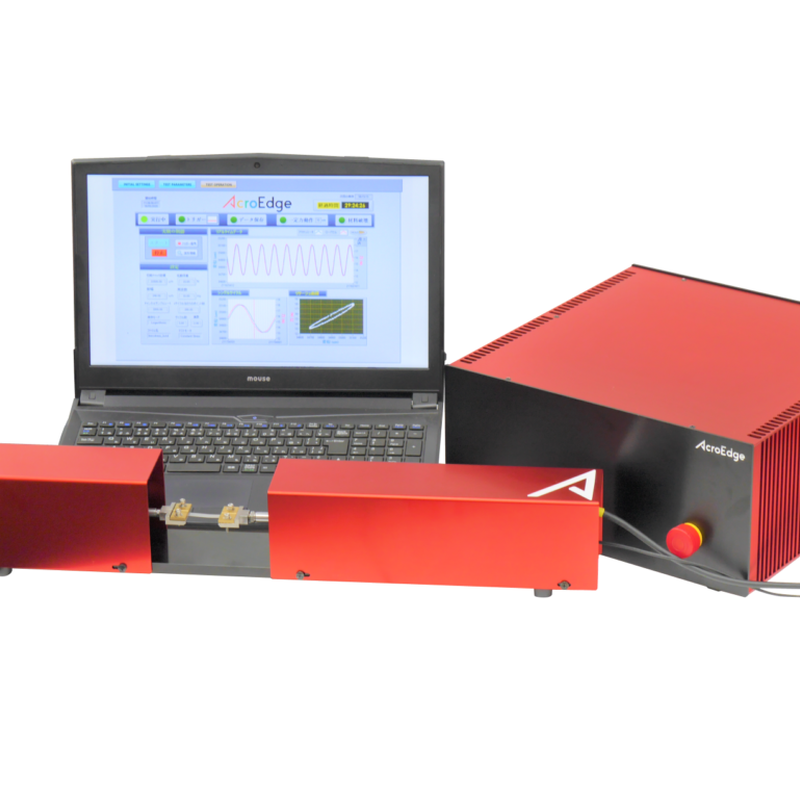

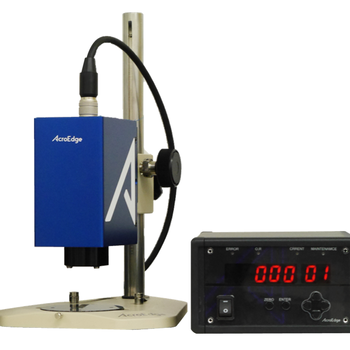

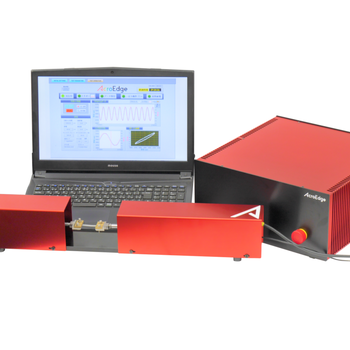

Device configuration

- controller

- Fatigue Testing Machine

- PC for data collection and system control

Main specifications

- Power supply: 100V 10A

- Controller dimensions: L250 x W250 x H150 [mm]

- Fatigue test machine dimensions: L100 x W100 x H500 [mm] Vertical configuration

- Controller weight: ~5 kg

- Fatigue tester weight: ~3 kg May vary

Hardware can be freely designed according to your needs.

Rated Experimental Parameters/Operating Limits

- Frequency range: 1 to 20 Hz

- Maximum amplitude: ±600μm

- Force range: ±25 N ±0.5% nonlinearity

Sample dimensions

- Length: 25-35 mm Thickness/diameter negotiable

- Width: Maximum 20 mm Shape: Film, fiber, etc.

Other features:

[Operation mode]

Operating mode (tension-tension / tension-compression / compression-compression possible)

-Constant strain: Default mode/Tests with a constant strain waveform.

- Constant Stress: The constant stress motor maintains a constant load on the material in response to a decrease in the load on the load cell. The operating parameters during stress decrease can be set as desired .

[Save mode]

- Linear mode: User input is a mode that saves [N] cycles every [T] minutes.

- Logarithmic mode: Data is saved in logarithmic scale. [N] cycles of data are saved in logarithmic scale (10, 100, 1000, …, 10×).

Up to 10 cycles can be acquired per saved event.

PC software: data acquisition and system control

A software program for data collection and system control.

The PC and control unit are connected via USB for data collection and system control.

Settings screen

Test condition settings: Amplitude, frequency, storage interval, gauge length, etc. (Tension – tension / tension – compression / compression – compression are possible)

A function to apply an initial load to the material before vibration testing.

Destruction trigger: Set the set value for material destruction. If the value falls below this, the material is determined to have been destroyed,

The program will automatically stop and save the last 3 cycles before destruction.

Sampling rate: 2000 points/s

(Example) Frequency 20Hz: 100 points/1 cycle, Frequency 5Hz: 400 points/1 cycle

Real-time monitor

Real-time load and strain monitoring

Acquired data (Excel compatible format): Time, stress, strain

The chuck shape, power output, and control system can all be customized to meet your needs.

AAdmin

Welcome, honored guests. Please leave a comment, we will respond soon