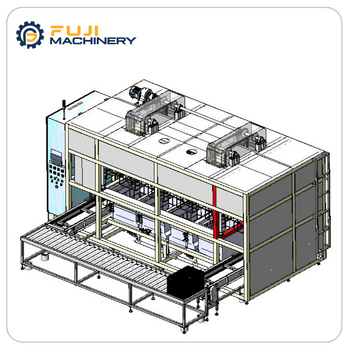

KleanX Cutting Oil Tank Cleaning Machinea

5 (1 đánh giá)

The KleanX Oil Skimmer Machine is designed to meet the growing demands for high performance and environmental protection in the metalworking industry.

Utilizing advanced technology, the system not only removes metal chips, sludge, and other contaminants cutting oil tanks, but also enables efficient oil recycling, helping save time and optimize operational efficiency.

The KleanX cutting oil tank cleaning machine, developed through our own research and engineering, is a versatile solution compatible with all types of metal machining equipment.

With the ability to quickly and efficiently remove metal chips, sludge, and other contaminants cutting oil tanks, this machine enables effective cutting oil recycling while significantly reducing cleaning time.

As a result, it not only enhances production efficiency but also reduces operating costs compared to manual cleaning methods.

Thanks to its flexibility and practical design, the KleanX cutting oil tank cleaning machine is not only a smart choice but also a key lever for optimizing production processes in metal machining workshops.

TECHNICAL SPECIFICATIONS

| Item | Model / Specification | |

|---|---|---|

| CL-100 | CL-200 | |

| Operating power | Compressed air | Compressed air |

| Pressure range | 0.4 – 0.7 MPa | 0.4 – 0.7 MPa |

| Air hose diameter | 10 mm | 10 mm |

| Air consumption | 1 – 1.7 m³/min | 1 – 1.7 m³/min |

| Maximum suction distance | 5 m | 5 m |

| Maximum flow rate | 100 L/min | 200 L/min |

| Filter basket capacity | 9 L | 15 L |

| Filtration grade | Standard Mesh 40 (customizable) | Standard Mesh 40 (customizable) |

| Max. particle size | 10 mm | 10 mm |

| Fluid viscosity | ≤ 3000 cps (25°C) | ≤ 3000 cps (25°C) |

| Operating temperature | 0°C – 60°C | 0°C – 60°C |

| Machine dimensions | L600 × W400 × H960 mm | L600 × W400 × H960 mm |

| Weight | 67 ± 1 kg | 67 ± 1 kg |

APPLICATIONS

The cutting oil tank cleaning machine effectively removes metal and non-metal chips, sludge, and accumulated residues coolant tanks of machining equipment. This helps maintain stable machine operation and performance while protecting critical components damage caused by contaminants.

Beyond cleaning applications, the system can also be used as a multi-purpose industrial pump, suitable for transferring wastewater, coolants, and water-based fluids. This versatility makes it a valuable tool for fluid management in production environments.

However, the machine is not suitable for non-volatile oils or corrosive liquids, such as strong acids, alkalis, or organic solvents. This limitation should be observed to ensure safe and reliable operation.

.jpg)

KEY BENEFITS

- Minimizes cutting tool wear, improving machining accuracy and reducing tool replacement costs.

- Prevents oil degradation and extends cutting oil service life, lowering maintenance expenses.

- Reduces industrial waste through effective oil recycling, contributing to environmental protection and resource conservation.

- Improves workplace cleanliness and safety by removing harmful substances and contaminants cutting fluids.

- Helps create a safer, healthier, and more efficient working environment for factory personnel.

.jpg)

.jpg)

Contact Fuji Machinery today to receive a special quotation for the KleanX Cutting Oil Tank Cleaning Machine

Smart cleaning solutions for every machining workshop

(+84) 964 658 958 | info@fujimachinery.com.vn

AAdmin

Welcome, honored guests. Please leave a comment, we will respond soon